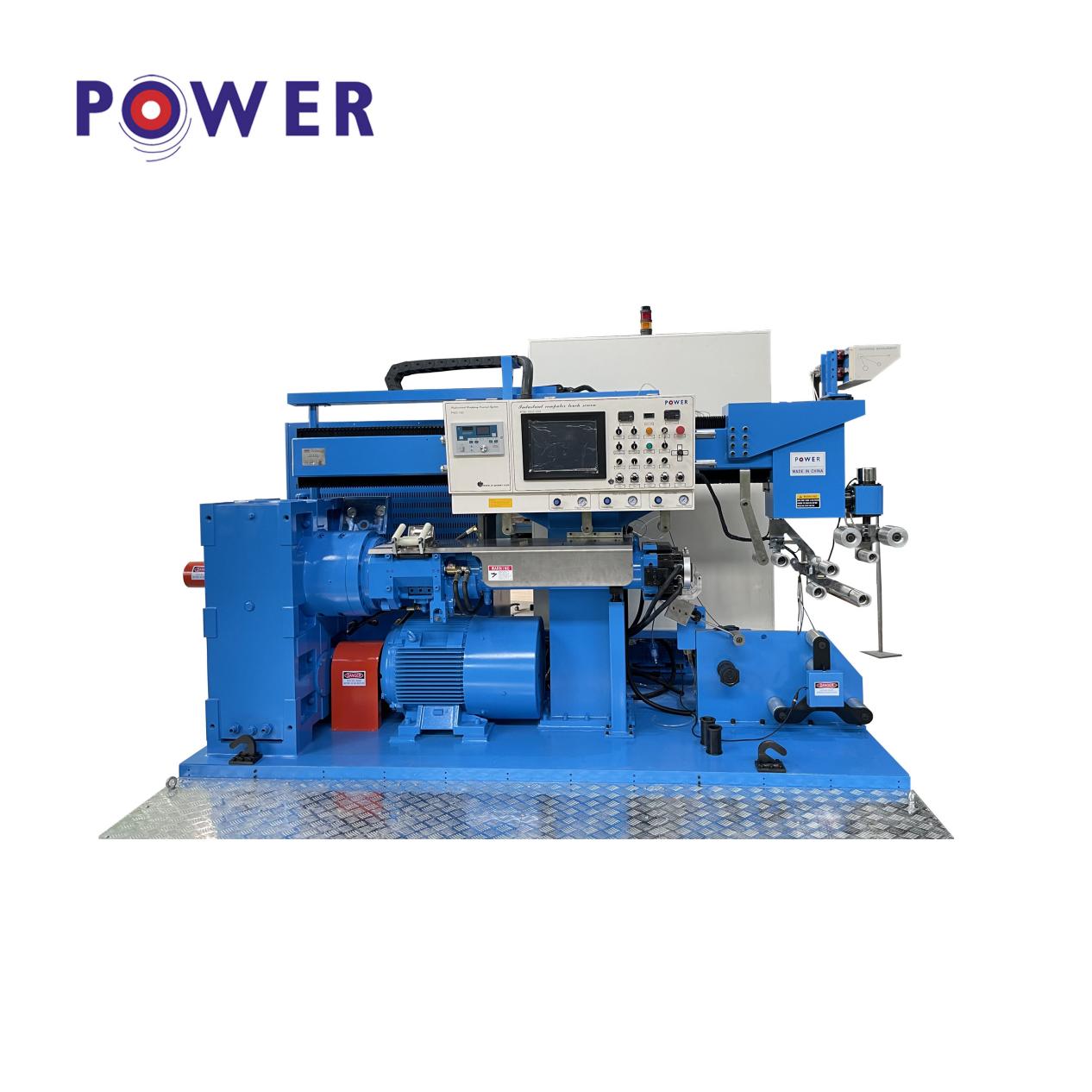

Mashiinka daboolida ee otomatiga ah ee tooska ah ayaa loo qaabeeyey oo la soo saaray si loo wanaajiyo loona hagaajiyo geedi socodka la-socodka. Moodooyinka ku habboon ayaa loo xulan karaa warshado kala duwan, iyo qalab horumarsan oo qaan-gaar ah ayaa ku soo kici doona hufnaan sare oo wax soo saarkaaga ah.

Tilmaamaha mashiinka daboolka duuban ee duuban:

1. Waxay ku habboon tahay soo saarista duubista caagga ee warshadaha culus, sida: birta iyo ka shaqeynta qotodheer, daabacaadda, daabacaadda iyo dheehda iyo dheehaynta iyo caynkaynta iyo farta kale ee ku-gudbinta tuubbooyinka.

2. Waxaa lagu qalabeeyay e300cs awood u leh 76 Qiyaasta Quudinta Qabow iyo Nidaamka qaboojiyaha oo dhammaystiran;

3. Ku habboon caag isku dhafan oo adag oo adag;

4. Balaadhinta shaqa-dheellitirka ee qaybaha gaarka ah ee qaybaha duuban ee caagga ah ayaa la dooran karaa;

5. Guud ahaan, daabacaadda cajaladda cajaladda ayaa soo saari kara 40-60 gogo 'halkii isbedel.

Dhibaatooyinka suurtagalka ah iyo xalka mashiinka daboolka ku daboolan caag.

Mashiinka ma dhaqaajiyo markii la bilaabo:

1. Saamiyada ugu weyn ee korantada ma aha mid ku xirna hubinta korantada dibadda iyo dib-u-awood

2. Korontada xakameynta korantada kuma xirna. U adeegso furaha furaha si aad u shiddo korantada ama u xir wareejinta golaha korantada ee korantada.

3. Riix batoonka hakinta oo mar labaad riix si aad u soo baxdo

4. Riix batoonka joogsiga degdegga ah oo sii daa batoonka joogsiga degdegga ah

5. Plc waa wax dhaawacmay oo la beddelay

6. Dib u soo celi xargaha korantada iyo qalabka kale si aad u hesho korantada madaxa-bannaan

Burburinta ma wareejiso:

1. Inverter waa la gubay, oo ifafaaleyaashu ma jiraan wax soo bandhigid ah. Beddelid

2. Qiyaasta ka mid ah kuwa wax qabadku si qalad ah ayaa loo dejiyaa. Mar labaad u deji marka loo eego shuruudaha.

3. Silsiladda wareegga ayaa jabtay. Hagaaji masaafada u dhaxaysa gibiyaha waaweyn iyo kuwa yaryar oo isku xir silsiladda. Haddii silsiladdu waxyeelloobeen, beddel silsiladda.

4. Moodada wareega laftiisa ayaa khaldan. U adeegso balaaran ama gariir si aad u hubiso in matoorku maqan yahay ama uu jabay. Haddii lagu hagaajin karo goobta, beddel matoorka.

5. Qiyaasida isuduwaha laftiisa ayaa qalad ah, bedel

7. Plc ma leh wax soo saarka wax soo saarka

8. Xiriirka dhex maray canada iftiinka udhaxeeya iyo in la soo geliyo ayaa ah mid aan caadi ahayn. Beddel furaha isku xirka isku xirka

Gawaarida mashiinka dabaysha ayaa u baahan in lagu riixo inuu bilaabo:

1. Waqtiga bilowga ah ee shirkadda bilowga ah ee bilowga ah ayaa aad u dheer. Dib u dejiso.

Burburinta ma joogsato

1. Duufaanta qashin-qubka ayaa dhaawacmay. Dib-u-habeyn isbadal.

Burburinta ma bilaabi karto ama si tartiib ah u joogsan karin:

1. Qiyaasta xudunta ee qalinka ayaa si qalad ah loo dejiyay. Dib u dejin

Waxaa jira buuq ka dib wareegga wareegga:

1. Dhulku waa mid aan sinnayn. Isticmaalaha waxaa looga baahan yahay inuu xalliyo ama la beddelo meesha meelaynta.

2. Xirmooyinka culus ee la taaban karo oo ah kuwa taageerayaasha shaqsiga ah ayaa beddelaya rollers taageera

Inverter-ka wuxuu soo bandhigayaa qaylo dhaanta xad-dhaafka ah iyo korantada waa mid aan degganayn. Hagaajinta tayada korantada ama hagaajinta inta jeer ee loo beddelo dardargelinta dardargelinta iyo waqtiga khiyaanada.

Burbur ku yimaada isku xirka iskuxirka caagga ah iyo iskuxirka filimka (usha barbaarinta):

1. Haddii ay waxyeelloobo inta lagu jiro gaadiidka, beddelo

2. Si dabiici ah ayaa u dhacay oo la beddelay

Xawaaraha Quudinta Filimka lama hagaajin karo:

1. Sanduuqa kontaroolada xawaaraha ee DC ayaa dhaawacmay oo wax soo saar wax soo saar ah ma leh. Beddel

2. Giraangiraha pallet-ka shaqsiyeed si xun ayaa loo xidhaa, iyo giraangiraha taageeraya waa in la beddelaa.

Waqtiga Post: Aug-11-2022